NEWS

Project Presentation at the IUFRO World Congress

The IUFRO World Congress took place from 23.06. to 29.06.2024 in Stockholm. IUFRO World Congresses are among the largest global forest-related events and are interdisciplinary and integrative in scientific content. They are a forum for scientists and stakeholders to discuss technical and societal issues in forest-related research, policy-making and management. Theresa Boiger from the Institute of Environmental Systems Science at the University of Graz, scientific partner in the CARpenTiER research project, presented an optimization of wood value chains with regard to climate protection, which is being carried out as part of the project.

Stockholm, Sweden

23.-29.06.2024

Pictures: © CARpenTiER / TU Graz

Project Presentation at the European Lightweight Construction Network Conference

The Austrian Advanced Lightweight Technology (A2LT) The A2LT unites the capabilities of Austrian companies and research institutions in the field of lightweight construction. Regardless of industry and material, innovative solutions are created through cooperation that exceed the capabilities of the individual members. As part of its membership, W.E.I.Z. Forschungs & Entwicklungs gGmbH was invited by the BMK to present its research activities on the topic of wood as a sustainable lightweight construction material for the mobility industry and the COMET research project CARpenTiER in a panel discussion at the 4th European Lightweight Construction Network Conference.

23.05.2025

Linz, Austria

Pictures: © Innovationszentrum W.E.I.Z.

Project Presentation as Part of the Long Night of Research in Weiz 2024

The Long Night of Research took place in Weiz for the first time on May 24, 2024. The Long Night of Research takes place every two years across Austria and is the largest event on science and research in Europe. 15 organizations and companies from Weiz took part, opening their doors at 11 locations in Weiz to present their research, development and innovation achievements to a wide audience of around 1.600 visitors. Among the companies was the W.E.I.Z. innovation center, which impressed over 900 visitors with its research on wood in new applications. The CARpenTiER project was also presented, and the results and content shared with many interested parties. One highlight was the hands-on station for children, where they could make their own spinning top out of wood. The different properties of the different types of wood were conveyed through the selection of disks made from different types of wood. The question arose: Which spinning top would spin the longest?

Weiz, Austria

24.05.2024

Pictures 1-3: ©Stadt Weiz / Pictures 4-6: ©Innovationszentrum W.E.I.Z.

Project presentation as part of the Graz Spring Fair

This year, the Graz Spring Fair focused on the versatile material wood. As part of this, the Styrian Wood Day took place on 29.04 in the Graz City Hall. The organizer proHolz Steiermark was able to inspire the audience with exciting presentations and interactive hands-on experiences about forests, wood and innovations. Weitzer Woodsolutions and Holzcluster Steiermark were also represented in the Stadthalle on this day and, as important project partners of the Comet research project CARpenTiER, were able to present and exhibit the innovative research and resulting demonstrators.

29.04.2024

Graz, Austria

Pictures: ©CARpenTiER/HCS

Project presentation at the 20th Wood Technology Colloquium

The Wood Technology Colloquium is a classic conference in wood research that focuses on wood in mechanical engineering. In addition to presentations on topics such as wood in mechanical engineering, calculation and safety concepts and process influencing variables for flow punch forming in wood-based materials, W.E.I.Z. Forschungs & Entwicklungs gGmbH and Weitzer Woodsolutions GmbH were also able to give two exciting presentations entitled "Ecologically sustainable lightweight construction" and "The transformation from a classic wood processor to a sustainable system supplier". They were able to present the research work from the CARpenTiER project and previous results and findings from the project to the audience.

28. - 29.04.2024

Dresden, Germany

Pictures: © Weitzer Woodsolutions

Presentation of the Project “CARpenTiER” at MotionExpo 2024

From March 8th to 10th, 2024, Graz played host to the motionExpo, a significant trade fair and conference focusing on innovations and technologies in the field of mobility. Among the prominent participants was the CARpenTiER project, which showcased its latest achievements. The motionExpo provided an ideal platform for the CARpenTiER project and its partners from industry and academia to present the progress made in the project to a wide audience and receive valuable feedback from experts and enthusiasts. With the Crash Management System being one of the highlights of these presentations, CARpenTiER solidifies its position as a pioneer in the development of cutting-edge technologies, utilizing wood as a lightweight application for safer and more sustainable mobility.

08.-10.03.2024

Graz, Austria

Pictures 1-3: ©Innovationszentrum Weiz

International Conference on Industrial Applications of Adhesives 2024

The IAA – International Conference on Industrial Applications of Adhesives is held every two years and in 2024 it took place in Cascais, Portugal. The focus of the conference is on applications of adhesive bonding in the industry such as automotive, aeronautic, railway, marine, energy, electronics, etc. The idea is to bring together the adhesive makers and the adhesive users to exchange experiences and facilitate potential synergies and partnerships. Eva Graf from the Institute of Materials Science, Joining and Forming at Graz University of Technology presented the research of the project CARpenTiER on the mechanical performance of adhesive-bonded aluminum-wood joints with different adhesive types.

07.-08.03.2024

Cascais, Portugal

Pictures 1-3: ©TU Graz

Anniversary Celebration 25 Years of VHÖ / 50 Years of Wood Studies at BOKU

On November 17th, the project partner BOKU hosted the 25th annual general assembly of the Association of Graduates of Wood Management and Wood and Natural Fiber Technologists (VHÖ) and celebrated 50 years of wood management studies. During the event, the manufactured showpieces from the WoodC.A.R. and CARpenTiER projects were exhibited and presented to graduates and invited guests. The evening event was hosted by Dipl.-Ing. Christian Tippelreither from the project partner Holzcluster Steiermark. In a video message, Federal Minister Norbert Totschnig MSc pointed out the importance of the "wooden" branch of study for the Austrian economy and the key role of wood as a raw material in overcoming the climate crisis, which was taken up again and further deepened in the keynote speech by Prof. Dr. Andreja Kutnar, University of Primorska in Koper, Slovenia, entitled "Wood and Climate Crisis". Finally, the anniversary brochure 50 years of the timber industry and 25 years of the VHÖ was presented by Johannes Plackner, Chairman of the VHÖ, and the ceremony ended with a photo review.

17.11.2023

Vienna, Austria

Pictures 1-3: ©BOKU

Joanneum Research Conference "Green and Digital Transformation"

Yesterday, the impressive and with 700 participants very well attended conference of JOANNEUM RESEARCH under the title "Green and Digital Transformation" took place. In addition to an exciting program with keynotes by, among others, Univ.-Prof. DI Karl Rose, Chairman of the Supervisory Board of Energie Steiermark AG and Member of the Supervisory Board of OMV AG and Ms. DI Jacqueline Erhart Lead of CC AD and Digital Infrastructure of ASFINAG MAUT Service GmbH and Chairwoman of the Supervisory Board of AustriaTech GmbH, the individual institutes of JOANNEUM RESEARCH, including the MATERIALS Institute, which has been located at the Innovation Center W.E.I.Z. for 25 years, gave exciting insights into their research work. Interesting topic sessions, many discussions in the context of networking and an exhibition on the topic of "Wood in new applications" with partners from the CARpenTiER project sponsored by the Innovation Center W.E.I.Z. rounded off the program. The CARpenTiER-Consortium congratulates JOANNEUM RESEARCH for this exciting day and their valuable contributions for society to the green and digital transformation.

16.11.2023

Graz, Austria

Pictures 1-6: ©JOANNEUM RESEARCH / Suppan

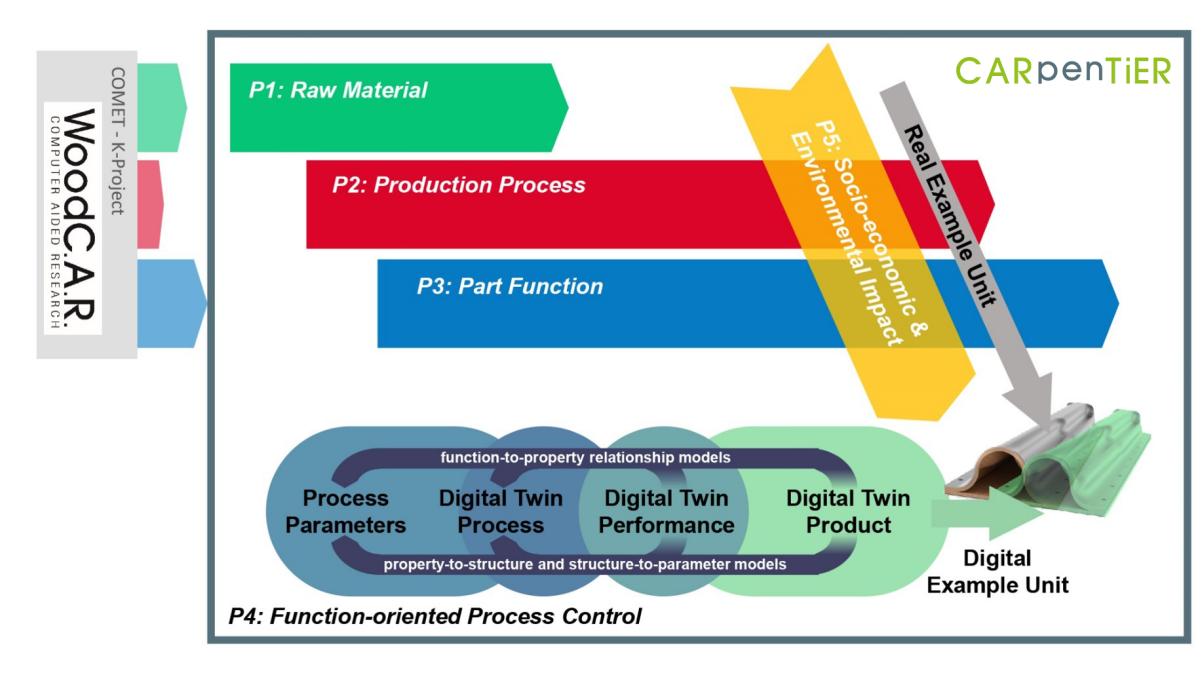

8th Consortium Meeting of the COMET-Project CARpenTiER

The 8th consortium meeting for the CARpenTiER project took place on 13 and 14 November 2023, this time at the project partner Fill Maschinenbau in Gurten. After introductory words by the consortium management, the Innovation Centre W.E.I.Z., the participants were given an impressive tour of the company and a detailed introduction to Fill and its activities. The scientific partners then presented their previous research activities to the consortium. The first day ended with a joint dinner and networking.

On the second day, the focus was on the centrepiece of the project – the Function-Oriented Process Control (FOPC). The proof of concept for this was achieved, an important milestone in the Carpentier project. Finally, the results to date were discussed together and further steps in the project were planned.

13.-14.11.2023

Gurten, Austria

Pictures 1-3: ©Innovationszentrum W.E.I.Z.

Project-Presentation at the Science Day of the University of Technology Graz with the Topic “New Worlds in Production”

The third science day of the University of Technology Graz “TU Graz – Science for Future” took place on-site at the Alte Technik Graz and consisted of various keynote lectures, pitch talks and poster sessions. In the frame of the Session “Biobased products and production” the CARpenTiER project was presented by Eva Graf from the TU Graz in terms of a poster, flyers and demonstrators about the forming, bending and joining of hybrid metal-wood components as potential application for the mobility sector.

More information about the Science Day at TU Graz: Science Day TU Graz

27.09.2023

Graz, Austria

Pictures 1-3: ©TU Graz

Moving On - ACstyria Mobility Congress 2023

From 26.09. to 27.09.2023, the ACstyria Mobility Congress took place at the Seifenfabrik in Graz under the motto "Moving On". The cluster partner ACstyria placed special emphasis on its strategic topics of digitalization and digital business models, innovative drive and vehicle concepts, autonomous systems, mobility services and decarbonized value chain. In addition to exciting presentations and discussions, the project CARpenTiER was presented at the exhibition the progress of the project was shared with experts from the industry.

Graz, Austria

26.09. - 27.09.2023

Pictures 1-2: ©ACstyria

Midterm Review of the Project CARpenTiER

Half-time of the project CARpenTiER - on this occasion the Midterm Review took place on September 19th with a review team consisting of auditors of the FFG, external experts on the project topic as well as participants from the Federal Ministry for Climate, Environment, Energy, Mobility, Innovation and Technology (BMK) and the Province of Styria. In an online meeting all previous results from the COMET project have been presented by all scientific partners and with the active participation of the business partners. The external experts were impressed by the consortium with its interdisciplinary and well-integrated value chain from the different industrial and research areas.

19.09.2023

Weiz, Austria

Pictures 1-6: ©Stadtgemeinde Weiz

Presentation of the Research at the FEMS EUROMAT 2023

The FEMS EUROMAT is the premier international conference for the latest advancements in materials science and technology in Europe. In 2023 the congress took place at the Goethe University located in Frankfurt, Germany. Eva Graf from the Institute of Materials Science, Joining and Forming (Institut IMAT) at Graz University of Technology presented the research on the three-point bending behavior of hybrid aluminum-wood plates. Kevin Vitzthum from the Innovation Center W.E.I.Z. demonstrated a preliminary study on the feasibility of joining wood and steel with flow drill screws. The congress was another possibility to present the “CARpenTiER” project to the scientific community.

More information about the conference: EUROMAT 2023

03.09. - 07.09.2023

Frankfurt am Main, Germany

Pictures 1-3: ©CARpenTiER/W.E.I.Z. / TU Graz

The Last Mile Made out of Wood - Fresh Ideas for a Well-Known Raw Material

The TU Austria Innovation Marathon took place for the ninth time as part of the Europe in the World Days of the European Forum Alpbach. International students developed products and proposed solutions for future-oriented tasks for innovative mobility concepts. The consortium of the COMET project CARpenTiER also participated with the question: "Think the unthinkable and reduce the use of plastic and aluminum in the automotive industry, rail transport and mechanical engineering by replacing wood." The students were able to find many new ideas for wood applications in mobility, such as floor mats or grab handles, wooden bicycles or e-scooters and got an impression of how the substitution of plastics and metals by wood as a lightweight application can shape the future of mobility.

More Information about the TU Innovation-Marathon: Innovation Marathon - Video Holzcluster Styria

28.08 - 29.08.2023

Alpbach, Austria

Picture 1-3: ©Holzcluster/Schmid

Event "evon up2date"

In the Garden of Generations in Krottendorf/Weiz the annual event up2date of the project partner evon took place on 21st of June 2023. During the event, Thomas Krenke from the Innovation Centre W.E.I.Z., representing the partner Weitzer Woodsolutions GmbH, was allowed to give a presentation on the topic: "Digital transformation as the basis of ecological lightweight construction and the change of a classic woodworker on the way to Tier 1". In addition to this presentation Bernadette Karner from the Consortium Leader Innovation Centre W.E.I.Z. presented the research field and the progress of the research project CARpenTiER.

21.06.2023

Weiz, Austria

Picture 1-3: ©evon GmbH

Geco Festival - Graz Becomes an Oasis of Sustainability

The Geco-Festival, Styria's largest sustainability festival, took place in the city centre of Graz from 02.06. - 04.06.2023. The programme ranged from a sales market on the main square and a clothes exchange to the annual Graz Environmental Circus, exciting panel discussions and a series of workshops. The "CARpenTiER" project was also presented to a wide audience by project partner Karl-Franzens-Universität Graz - Institute of Environmental Systems Science.

02.06. - 04.06.2023

Graz, Austria

Picture 1-4: ©Karl-Franzens-University Graz

.jpg?v=1il4coj)

.jpg?v=1il4coj)

Presentation of the Project “CARpenTiER” at MotionExpo 2023

The MotionExpo is a symbol for the merging of innovation, information and emotion on the subject of mobility. One year after the premiere, this format entered the second round as the largest vehicle trade fair and mobility platform in Austria. Numerous innovations and further developments characterize the image of the MotionExpo2023. And among this year's exhibitors, the "CARpenTiER" project was also presented in hall C, where the latest technologies of the future could be found. The partners of the consortium were able to have many interesting discussions with trade fair visitors. In addition, Dr. Ulrich Müller, project manager of the scientific partner BOKU Vienna, could inform in the frame of the panel discussion “Innovative Vehicle Development” about the advantages of wood for use this renewable material in the mobility sector.

More information at: MotionExpo

10.03. - 12.03.2023

Graz, Austria

Picture 1-6: ©CARpenTiER/W.E.I.Z.

Exciting Lectures and Discussions in a Casual Location

That was the Green Tech Innovators Club on October 18th, 2022 in the MAKERSPACE Carinthia, where a wide variety of future makers from the Green Tech scene from Styria and Carinthia met and exchanged ideas about a wide variety of innovations, project ideas and opportunities for cooperation. To this event the consortium was also invited to present the "CARpenTiER" project and the existing partner consortium. Representing the entire consortium, Bernadette Karner and Thomas Krenke from the Innovation Centre W.E.I.Z. and Christian Tippelreither from Holzcluster Steiermark were discussing after the keynote speech why wood can be a very good alternative for many new applications in comparison to conventional materials. Many thanks to the Green Tech Cluster for the invitation and the excellent event.

More information at: Green Tech Innovators Club

18.10.2022

Klagenfurt, Austria

Picture 1-3: ©Helge Bauer

Moving ON - ACstyria Mobility Congress

Congratulations to the cluster partner ACstyria on their 25th anniversary. Around this anniversary, the two-day “Moving ON ACsytria Mobility Congress” took place on 11th and 12th of October at the Redbull-Ring in Spielberg. The congress was characterized by numerous visitors, various exhibitors, exciting lectures and many opportunities for networking and interesting discussions. The "CARpenTiER" project was once again presented to a broad audience in this context.

A review can be found here: Video - ACstyria Mobility Congress

11.10.- 12.10.2022

Spielberg, Austria

Picture 1-4: ©ACstyria Mobilitätscluster / Picture 5-6: ©Holzcluster/Schmid

CARpenTiER at the S-LCA Conference in Aachen

Claudia Mair-Bauernfeind from the partner institute for system sciences, innovation and sustainability research at the University of Graz (KFU) spoke at the 8th international conference of S-LCA about the sectoral social risks of the wood processing industries in Austria. As part of her presentation, she looked closer into the wood value chain and previous research results. In addition, Mrs. Dr. Mair-Bauernfeind gave an outlook on further research goals and possible applications for business, science and politics.

More information about the conference: SLCA Conference

05.09.- 08.09.2022

Aachen, Germany

Picture: ©KFU

CARpenTiER at the International Wood Fair in Klagenfurt

After a few years of a break due to Corona, the International Wood Fair “Wood & Construction” took place again in Klagenfurt from August 31st to September 3rd, 2022. In the exhibition area of the Innovation Area, co-organised by the network partner Holzcluster Steiermark GmbH, the "CARpenTiER" project was also presented. With CARpenTiER the consortium is driving further steps in the industrialization of bio-based, lightweight-optimized wood-hybrid construction concepts, which was presented in Klagenfurt by the industrial partners LEAN MC and Glanzstoff as well as the scientific partners Virtual Vehicle Research GmbH, the TU Graz and the consortium leader Innovation Center W.E.I.Z.

31.08 - 03.09.2022

Klagenfurt, Austria

Picture 1-4: ©Holzcluster / Picture 5-6: ©Innovationszentrum W.E.I.Z.

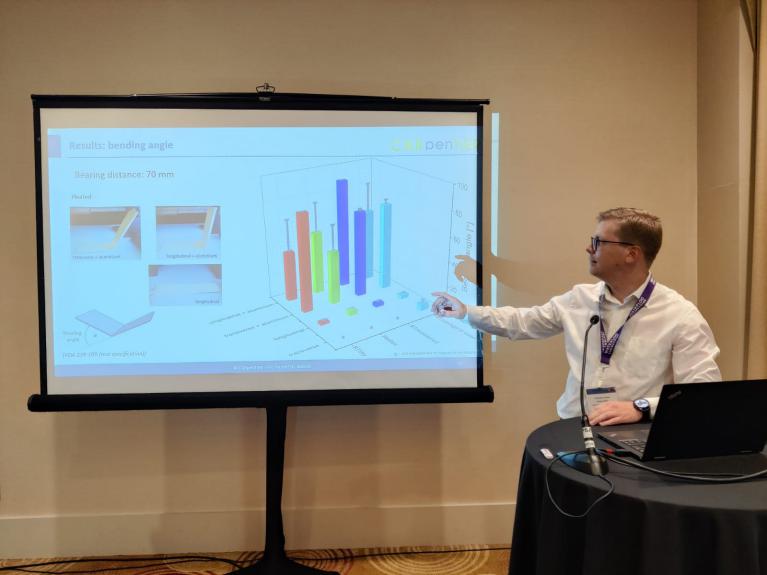

Bending Deformation of Hybrid Aluminium-Wood Sheets for Automotive Lightweight Applications

NUMISHEET- Conference 2022 in Canada

Hybrid sheets of 1-mm-thick EN AW-6016-T4 aluminum alloy and 4-mm-thick birch wood were produced by adhesive bonding. Wood fibre orientations parallel as well as perpendicular to the rolling direction of the aluminum sheet were considered. After curing the adhesive, the hybrid aluminum-wood sheets with overall dimensions of 250 mm × 60 mm × 5 mm were subjected to three-point bending.

Hybrid sheets (i) as fabricated at room temperature, (ii) moistened at room temperature, and (iii) moistened at approx. 100 °C were tested. Two bending modes were investigated, since either the aluminum sheet or the wood sheet was placed at the punch side. Moreover, a finite element model of the testing setup was built using the LS-Dyna software. Experiments were performed for determining individual properties of aluminum and wood which were used as input for the model. Punch forcedisplacement curves and deformation behavior observed in experiments and simulations showed good agreement.

10.07. – 14.07.2022

Toronto, Canada

Picture 1-2: ©TU Graz/IMAT

How Much Wood is in a Car? CARpenTiER Live at the Long Night of Research

Every two years the “Long Night of Research” is carried out at 280 locations all over Austria. After a forced break in 2020, this year on the 20th of May 135 000 visitors took the chance again to get a live insight into science and research of various fields. The event aims to present the importance of scientific research for all ages and especially lets children and young people experience the daily works of scientists up close. From guided tours to live experiments and join-in activities the concept is led by a hands-on and easily accessible way of knowledge transfer.

The CARpenTiER project team took the chance and presented the first results, goals and challenges in establishing wood and renewable materials in the mobility sector. With the sounds of cracking wood under a live bending test of a cars side impact beam, the attention of the audience was easily captured. Many were surprised to learn that the bio-based beam can reach the same standards as the steel version with the crucial benefits of weight savings, greenhouse emission reduction and lower primary energy use.

The exhibition of the bus staircase and wooden chassis of a snowmobile from the predecessor project WoodC.A.R. facilitated the transition to the current CARpenTiER research questions on enabling the use of wood and overcome the challenges of the variability of natural raw materials in a modern industrial production. On that night 1500 visitors at the BOKU-lab in Tulln learned about the projects approach via digital modelling of example units and function-oriented process control. Quickly, the interested discussion with the presenting team from BOKU and Innovation Centre W.E.I.Z. on the stations general question “how much wood is in a car?” turned into “how much wood could be in a car in the future?”.

20.05.2022

Tulln, Österreich

Picture 1-2: ©CARpenTiER/W.E.I.Z.

ACstyria Lightweight Day 2022

As in previous years, the “ACstyria Lightweight Day 2022” took place on March 30th 2022 at the RedBull Ring in the Austrian Spielberg, in cooperation with the A2LT – Austrian Advanced Lightweight Technology platform. All in all around 130 participants and around 20 exhibitors took part. This year again, current information about the "CARpenTiER" project has been presented.

In specialist lectures, the audience was informed about new trends, ongoing developments and projects on the major topic of lightweight construction. Across the three sectors of automotive, aerospace and rail systems, the speakers provided insights into topics such as materials, manufacturing processes and also testing techniques. In addition to insights into a wide variety of materials such as metals or composites, new insights into the use of sustainable materials such as wood or hemp in lightweight construction applications have been also presented.

"Wood will play an important role in the mobility industry in the future", this conviction of the CARpenTiER consortium was brought closer to the specialist audience by the lectures Christian Tippelreither, managing director of the cluster partner Holzcluster Steiermark and Thomas Krenke, scientific lead of the project and key researcher at the Innovation Centre W.E.I.Z. Thanks to the Cluster partner acStyria for providing this excellent platform year by year.

30.03.2022

Spielberg, Austria

Picture 1-4: ©Holzcluster/Schmid / Picture 5-6: ©ACstyria/Photoworkers

Second Consortium Meeting of the COMET-Project CARpenTiER

Finally, once again, a physical meeting of all project partners on the research field "Wood in new applications". On October 11th and 12th, as part of the “CARpenTiER” project, the 2nd consortium meeting took place in the Innovation Centre W.E.I.Z. took place and great joy of meeting was noticeable.

Full of energy and zest for action, the partners listened to the presentations of the master's theses “From laboratory to industrial scale: ecological upscaling effects in the production of wood components for the automotive industry” and “The acceptance of wood as a sustainable high-tech material in vehicles. An end-user perspective. "

Afterwards, the participants discussed the defined research questions of the CARpenTiER project, in the context of the extent to which the further development of production technologies on the basis of functional, digital-based process control is in focus. The aim of CARpenTiER is the development of production technologies for wood-based hybrid constructions in automotive, plant and mechanical engineering.

The meeting was rounded off by an impressive tour at the company of the industrial partner Weitzer Parkett.

11.10. - 12.10.2021

Weiz, Austria

Picture 1-7: ©CARpenTiER/W.E.I.Z.

Scientific Workshop in the Innovation Centre W.E.I.Z.

On September 2nd and 3rd, 2021, the kickoff workshop of the scientific partners - W.E.I.Z. Forschungs & Entwicklungs gGmbH, BOKU - University of Natural Resources and Life Sciences, Vienna, Karl-Franzens-University Graz, VIRTUAL VEHICLE Research GmbH and Technical University Graz - took place in the innovation center W.E.I.Z.

At the beginning of the 2-day event, the previous work of the scientific partners was presented. Based on this, pre-prepared tests were followed by forming tests in different variations with different wood samples, in order to demonstrate by means of practical tests what possibilities there are in the raw material wood and what limits there are for it.

The various findings were then discussed in small groups in order to determine the scientific activities in the first year of research.

The aim of the CARpenTiER project is to develop production technologies with which wood can be used efficiently in automotive, plant and mechanical engineering. Not only the material wood, but also the associated manufacturing processes for industrial production should become economically efficient, controllable and reproducible.

In addition, suitable methods for woodworking and processing are to be developed in order to conserve resources and to maximize the use of raw materials in production.

02.09. - 03.09.2021

Weiz, Austria

Picture 1-7: ©CARpenTiER/W.E.I.Z.

Kickoff

On June 23, 2021, the kickoff meeting of the project “CARpenTiER‘‘ with the science and business partners took place in the form of an online event. Activities for the first year of research were defined and the entire project consortium was presented in detail. CARpenTiER is the successor project to the successfully completed WoodC.A.R. Project. As in the WoodC.A.R. project, the Innovation Centre W.E.I.Z. has taken over the consortium management in the CARpenTiER project.

The aim of CARpenTiER is to develop production technologies with which wood can be used efficiently in automotive, plant and mechanical engineering. Not only the material wood, but also the associated manufacturing processes for industrial production and the use of wood and wood hybrid components should be made predictable and manageable. In addition, suitable methods for woodworking and processing are to be developed in order to conserve resources and to maximize the use of raw materials in production.

You can find more information about the predecessor project here: Website WoodC.A.R.

23.06.2021

Online

The project CARpenTiER "Modelling, Production and further Processing of Eco-Hybrid Structures and Materials" is funded within the framework of COMET - Competence Centers for Excellent Technologies by BMK, BMAW and the Province of Styria. The COMET program is managed by the FFG.